Please let us know if you did not receive this email. rough mill, contour mill, etc.), each being a few minutes long, so it's definitely worth signing up for as a way to refresh yourself on different features. circular pocket, irregular slot, etc.) and operations (i.e.

They have over 4 hours of great videos on CAMWorks broken down into particular features (i.e. When you received your first e-mails after purchasing CAMWorks, there should have been a link to set up your account at SolidProfessor.

SolidProfessor (link to create account provided through initial email from Hawk Ridge Systems after purchase). Once opened, you can use Ctrl+F to do a quick search if you are looking for something specific. Each tutorial guide is labeled based off the subject they cover so be sure you are opening the correct file. Exercise 3.9B: Cam Assembly Copy all files from the Chapter. To access the tutorials from your SOLIDWORKS/CAMWorks interface, click Help > CAMWorks 2015, 2016, 2017 > CAMWorks Tutorials. Use the SOLIDWORKS toolbox to insert the needed gear components. The NC tab in the Operation Parameters dialog box and the interface of the Technology Database have updated and rearranged labels to improve the readability of CNC finish parameters.These resources are also available to help you resolve your CAMWorks issues and supplement your learning.īeyond the training manuals there are a number of tutorials and example files built in the software.

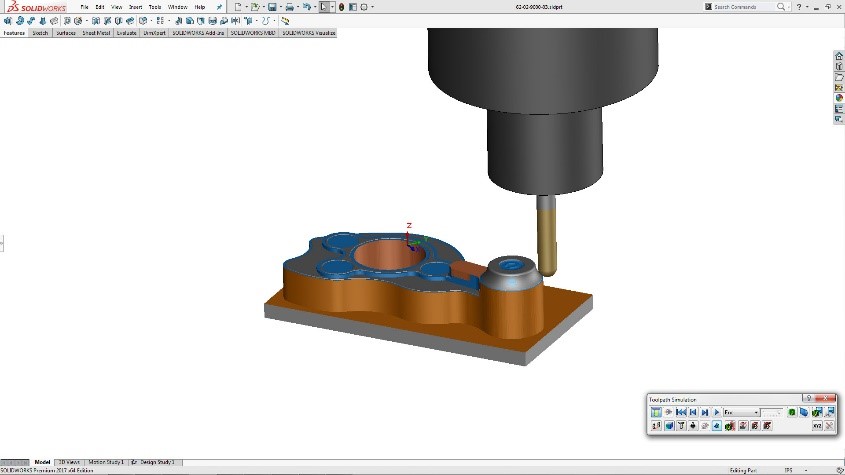

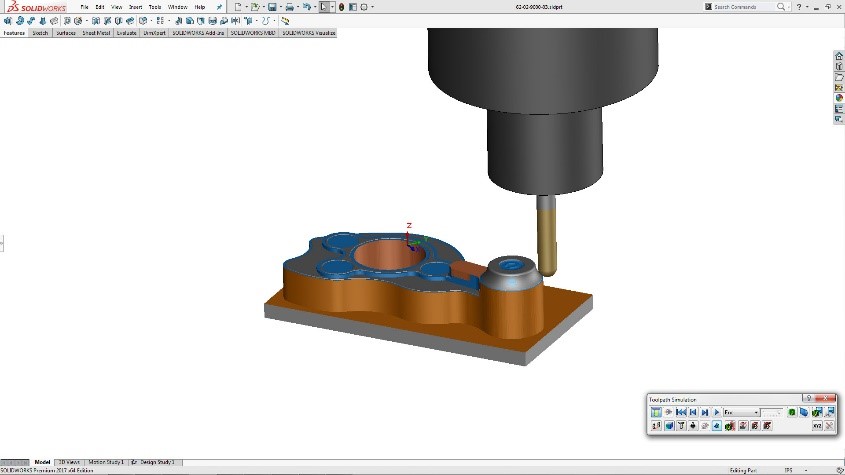

With CAM Professional, you gain access to assembly machining as well as programming for turning machines.

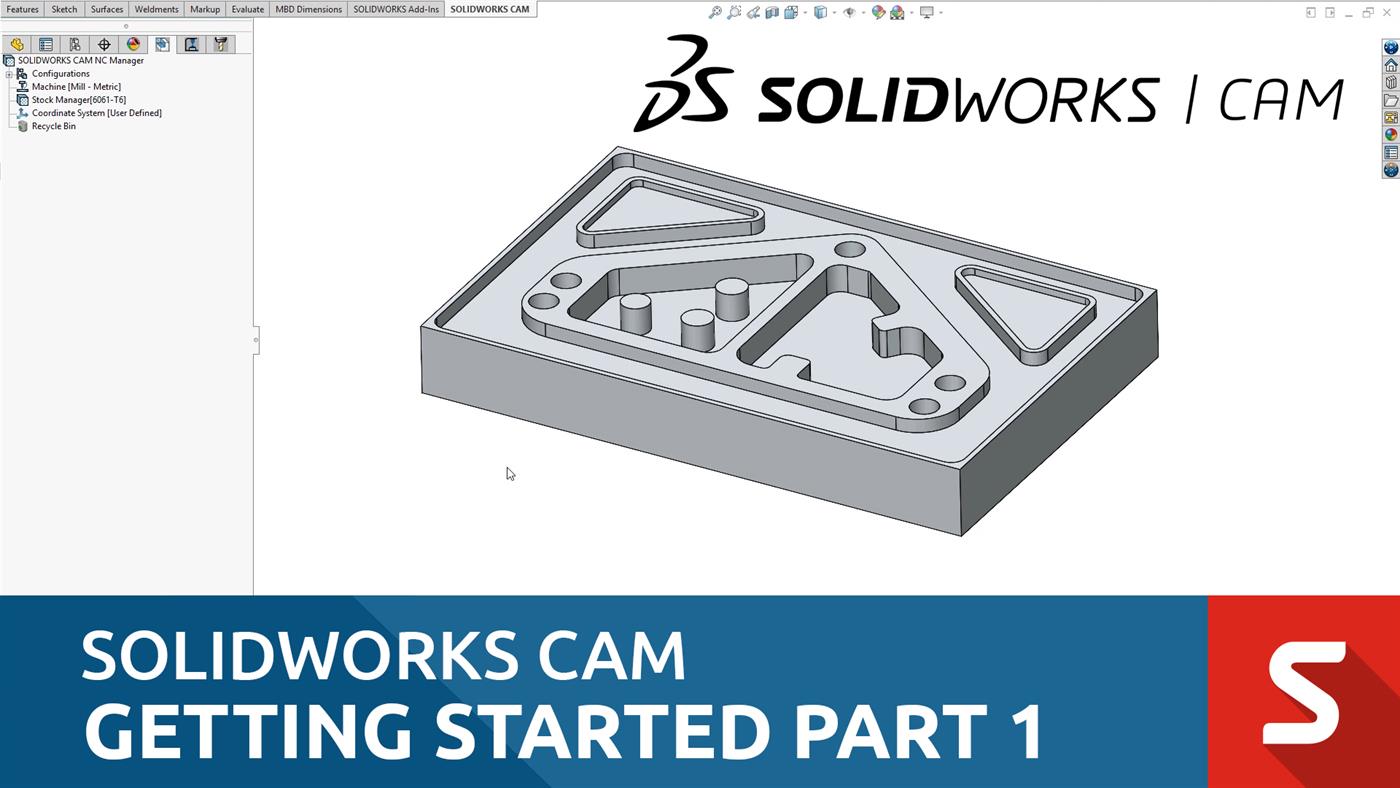

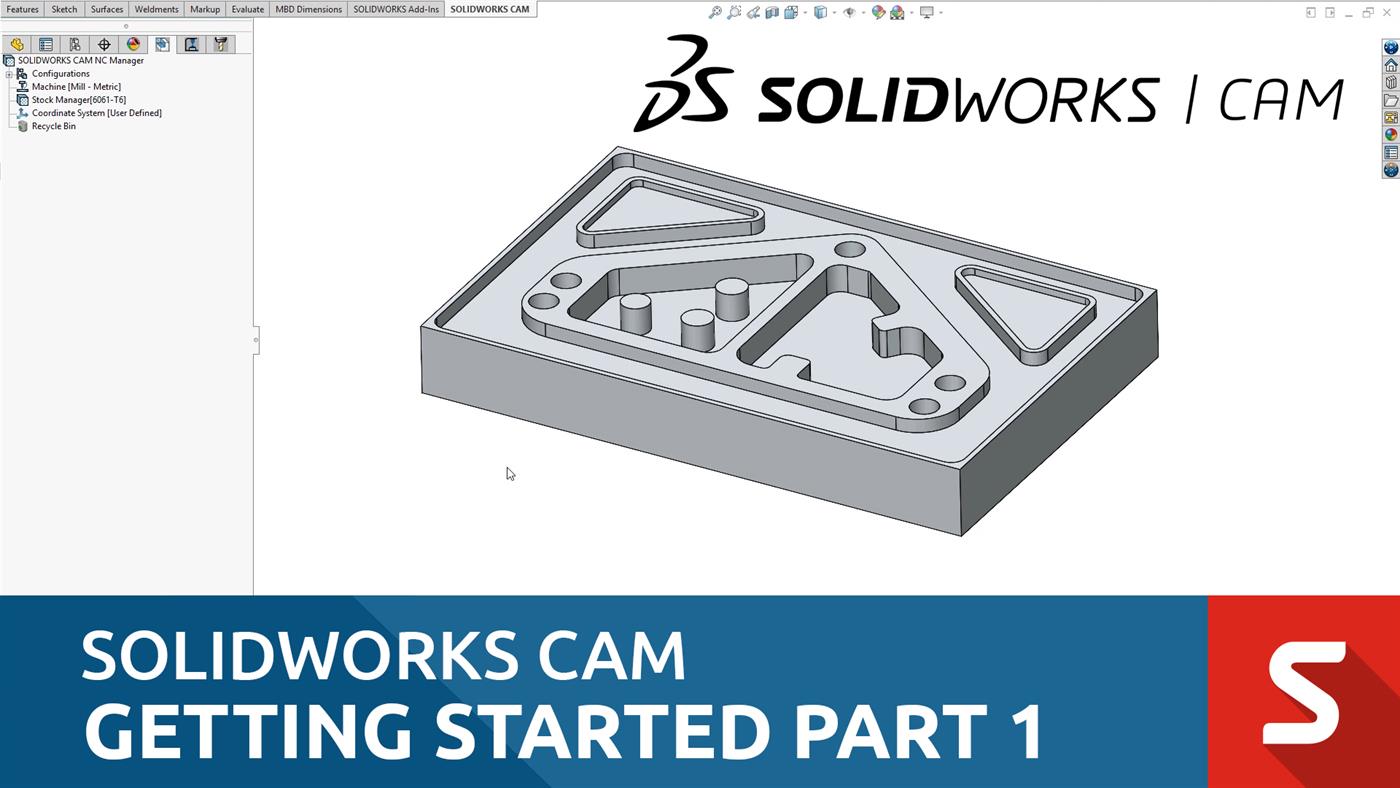

Revised CNC Finish Parameters for Clarity SOLIDWORKS CAM Professional allows for the same 2.5 and 3 Axis operations but also includes 4th and 5th axis position so your machine can index along those extra axes. You can select nonplanar surfaces in the direction of the Z axis for probe cycles. 35.6K subscribers Subscribe 7.5K views 1 year ago CAM & CNC Machining If you need to use SOLIDWORKS for CAM / CNC Programming, you are in luck. Support for Nonplanar Surfaces for Z Axis Probing.

You can manage multiple technology databases in the Manage Database tab. The Tool Select Filter dialog box lets you enter text to filter for mill and turn tools and assemblies.

Filter for Mill and Turn Tools and Assemblies with Text. You can select the follower track as a blind cut or cut through the entire cam. You can choose circular or linear cams with many motion types. In the Display tab of the Options dialog box, you can assign a color to display Toolpath hidden moves in the graphics area. Print Feedback on this topic Cams You can create cams with fully-defined motion paths and follower types. Display Color for Hidden Toolpath Moves. Customize Color Settings for Toolpath End Pointsįrom the Display tab in the Options dialog box, you can apply color settings for toolpath end points. Turn mode supports assemblies that contain a single Turn part model.

0 kommentar(er)

0 kommentar(er)